Attarat Oil Shale Power Project

Project Overview

In 2018, Orient Heavy Haulage (OHH) was awarded the transportation contract for Attarat Power Plant, which is the first oil shale-fired power project in Jordan. It is also the largest private sector project in Jordan to date costing USD 2.1 billion and the second largest oil shale-fired power plant in the world.

The project owner is Attarat Power Company; a partnership between YTL Power International, Guangdong Yudean Group and Eesti Energia. The project EPC is Guangdong Power Engineering Corporation, a subsidiary of China Energy Engineering Group.

Scope of Work

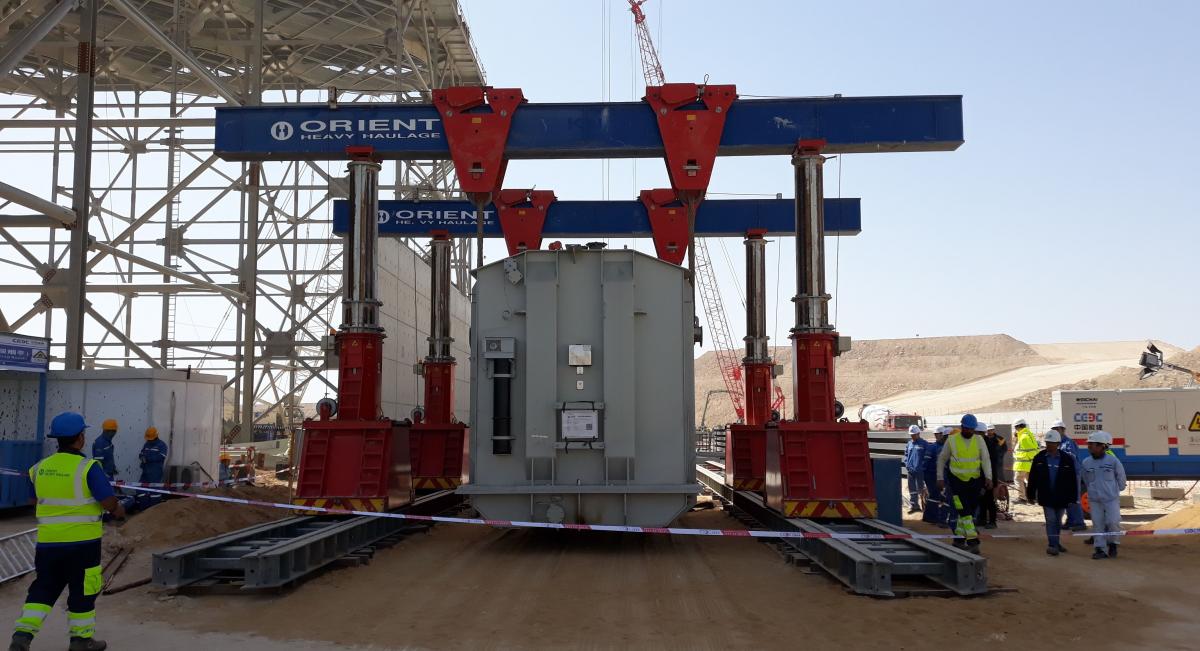

OHH scope of work included port handling and supervision, storage, and overland transport from port to site for all heavy lifts and oversized cargo. OHH was also responsible for the installation of heavy lift cargo on site.

The total volume handled by OHH for the project was approx. 200,000 FRT which consisted of 2509 heavy lift and oversized cargo. The main heavy lift cargo consisted of 2x 327mt Generators, 2x 210mt Transformers, 2x 149mt Boiler Drums & 2x 140mt HIP Turbine Sections. Oversized cargo included dimensions up to 10.05m in width and 7.50m in height.

The cargo arrived on 54 vessels spread over a period of 20 months. The first vessel arrived in Aqaba port on the 30th of March 2018. The maximum volume of heavy and oversized cargo received on a single vessel was 20,000 FRT.

An important contractually requirement was to deliver the cargo to site within 14 days after the arrival of the vessels, which was a requirement that we fulfilled successfully.

Resources Used

A team of approx. 45 employees worked on this project, which included a project manager, a transport engineer, an operations manager, a QSHE manager, safety officers, engineering supervisors, truck drivers, escort vehicle drivers, trailer operators, technicians, and riggers.

Many Heavy Lifts

The sheer number of heavy lifts received at the port which had to be delivered to site in a relatively short period of time imposed a serious challenge on our team and resources. For example, OHH had to deliver on average 30 heavy lifts per week. At peak times, that number reached 75 deliveries per week. Our engineers had to select suitable trailer combinations for the different heavy lifts and make sure that the resources are available at the right time to receive and deliver cargo to site.

New Port of Aqaba

The project started at a transition time when the port of Aqaba was moving to a new location. The new port was not working to its full capacity and was not able to handle the sheer volumes that were expected for this project. In addition, there was a problem with the route from the new port to the main highway; an alternative route for heavy lifts was not completed yet. Our company overcome this difficulty by successfully convincing authorities to allow us to use the old port until the problems were solved. This was a difficult process which involved several meetings with the authorities in Aqaba and the Ministry of Public Works. Had OHH not succeeded in this, the project would have faced serious delays.

Route Difficulties

The route from the port of Aqaba to the project site was an incredibly challenging route measuring 330km. It included many steep slopes of up to 12%, the most challenging being Nagab Uphill; a 9% constant slope for 15km starting at the desert of Wadi Rum and ending at Nagal mountain.

Driving in daylight meant that our prime movers had to be subjected to the extremely high temperatures of the desert while ascending the long steep slopes. Using prime movers with torque converters and cooling systems, as well as electronic synchronized capability, enabled multiple trucks to pull transport gross combination weight of up to 550t without any problems.

Bridges Below Route

There were 17 bridges below the route; 14 of which were avoided by constructing bypasses next to the bridges. For the remaining three bridges, an alternative route or a bypass was not possible. Supporting the bridges was the only option. However, this was never done before in Jordan as the regulations of the Ministry of Public Works (MPW) forbids heavy lift cargo from crossing bridges and states that an alternative route must always be used.

Faced with this difficulty, OHH worked with engineers and obtained detailed designs of the bridges and proposed a solution for supporting them. The solution was reviewed and accepted by the MPW.

The towers were designed by our company in such a way that enabled them to be easily assembled by manpower within a relatively short period of time. This enabled the towers to be assembled and dismantled before and after every heavy lift transport.

Height Restrictions

There were eight height restrictions of 5.7m along the route which included bridges, signposts and power lines. Many packages were high with the maximum transport height of 8.50m. This required coordination with Electricity Distribution Company (EDCO) whereby mobile workshops were sent to cut power and lift cables at the required locations.

One of the power lines that posed a difficulty belonged to Jordan Phosphate Mines Company (JPMC). Cutting power was only possible at certain times. Transport times had to be adjusted to avoid disruption to the mine.

Road Works

During the execution of the project, the main highway was undergoing heavy construction works. There was a total of 10km detour sections which consisted of narrow roads. A lot of planning and coordination with civil contractors, authorities and police traffic department was required to limit disruptions to traffic and organize temporarily closures of the detours to enable heavy lift and wide cargo to pass.

In some cases, it was also required to increase the width between the construction roadside barriers, which required approvals from authorities and coordination with civil contractors.

Conclusion

In conclusion, OHH has successfully met the demands of the largest (to date) heavy transport project in Jordan by safely delivering all cargo to the project site on-time.

This involved careful planning with authorities whereby approvals were granted for using the old port of Aqaba and permits were given for the first time in Jordan to support bridges for heavy transport.

Engineering and the use of innovative technologies were also demonstrated in this project to overcome difficulties along the route such as the use of prime movers with synchronized electronic technology.

Furthermore, disruption to traffic was successfully minimized and managed during daytime transport and along road construction detours thanks to the careful planning with the police and contractors.

Number Of Heavy Lift Jobs

More Case Studies

Transport and installation of 14 units of heavy lift cargo. Cargo consisted of steam turbine generator, transformer and HRSG modules. Installation was carried out using gantry crane, jacking &

Orient Heavy Haulage completed the transport and installation of 81 units of heavy lift cargo including gas generators, gas turbines, steam turbine generator, transformers & HRSG modules. Installation